Ley Tricot is our Italian knitwear manufacturer, a family business we’ve been in close contact with from the beginning. A very special partner with whom we have grown a lot over the years, who’s very committed and has lots of love and passion for textile.

In 1983 Maria Elena joined the company of her parents in Carpi, Italy. The story of Ley Tricot started many years earlier with the work of Maria Elena’s parents, Luigi and Luciana, and her grandmother, Elva. "My grandmother was the seamstress in her hometown. I still have her original Singer sewing machine in my office," says Maria Elena. Luciana has inherited her mother’s passion and talent for making clothes, a passion that, after many years of experience, has become a true art. "When my mother Luciana met my father Luigi, they started working together and producing their own knitwear collections. When I joined the company in 1983, we decided to focus on finding new customers and brands, instead of producing our own collections, this was the moment the factory Ley Tricot was founded."

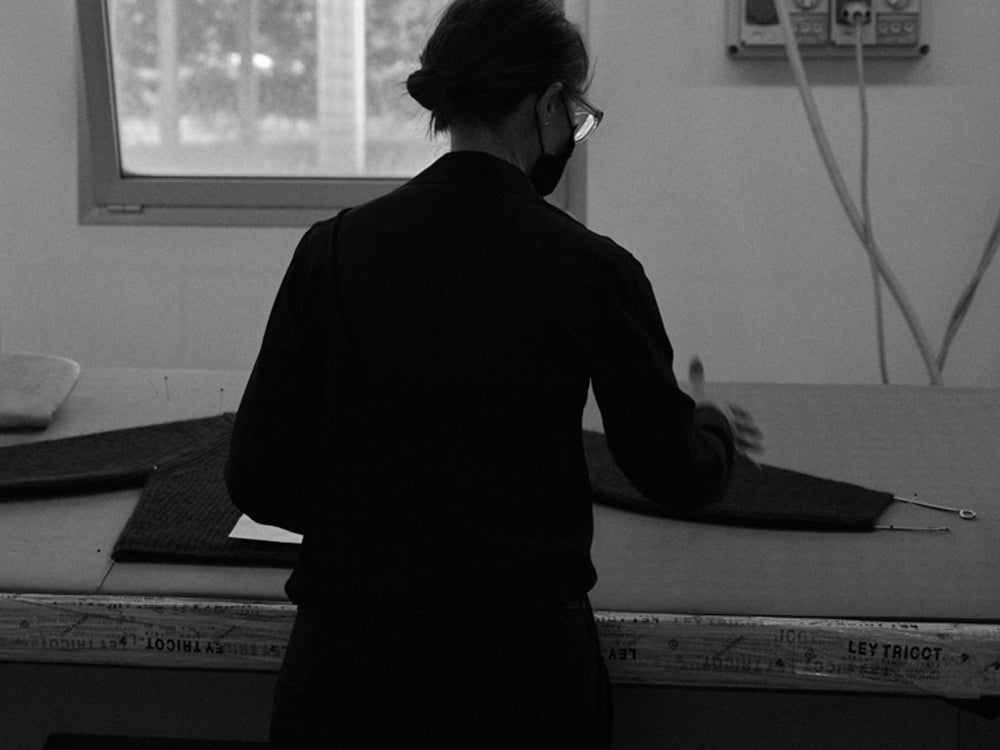

Maria Elena has developed her own professional skills since she was very young. "I started from scratch, making up colour cards in the summer when I should have been on holiday. I started helping my parents, I checked the lists when my parents were there, ironed and cut the first garments by hand. That’s how I fell in love with the job. I have always loved working with my hands, but I also love the creative interaction with different clients."

"Knitting is the only discipline where the maker is completely in control from start to finish, creating his or her own stitches, shapes, and finishes. Therefore you could say that knitting is probably the most creative of all clothing design disciplines."

- Maria Elena

To create a knitted Róhe pullover or cardigan, many steps have to be taken. The first step is to select the best Italian yarn. "We prepare two fabric swatches called “la tirella prova” for approval," explains Maria Elena. "One version is washed and the other is not. Then we plan all steps of the process from start to finish. It starts with knitting the panels, followed by vaporizing, linking, washing, doing all hand finishes like stitching the labels, shoulder pads, and eventually steaming each item."

"Steaming is an important step in the process of making a knitted item. This is necessary to achieve the final shape of the knitted piece. We follow a size chart with the exact dimensions of the item and use it to pin the shape and dimensions of the piece to the steam board. With the help of metal rods we mold it to create the desired silhouette. This setup with pins and rods ensures that the garment retains its shape during steaming. After this, we dry the piece and finally have our knitted garment in its definitive shape."

Ley Tricot grew step by step as a company and improved their knowledge every day. Technical skills come from practice, but a feeling for fashion and developing knowledge about innovation comes from exploring. Every Saturday, Maria Elena travels to Modena, Bologna, Mantova, and Verona to discover new trends and techniques. "I look to others to learn about new techniques and finishes. High-end brands employ seamstresses in their studios, who still do a lot by hand. It’s important for me to understand how they do certain things, I learn by looking at their work. To this day I am still learning new things, it never stops." This is one of the secrets of Ley Tricot, it ensures that they are constantly moving forward to achieve even better results.

Creating knitwear requires a lot of teamwork, nobody can do everything alone. Collaboration is important to achieve goals. "Many people on my team started working here at a young age and they have grown with the company." The result is a strong team of people with a lot of knowledge and experience. "My team knows that in this company you learn something new every day and that rules are made to be broken. They have a lot of patience with me, I am not easily satisfied, I always want to achieve perfection, I am a detail-oriented person, but in the end, when my team sees the lookbooks and campaigns of our clients with the results of their works, they are very proud to be a part of this.’"